As an engineer, my primary specialization is control systems. I spent much of my career in the aerospace industry, which uses high-performance control systems. Currently, I’m in the process industry that also utilizes control systems. While I’m less involved now in the actual control in terms of reporting overall performance, I’ve always been around control systems. So, it’s natural that I model business optimization using these systems. I use a control system for leadership and behavior modeling to manage organizations.

Control Systems

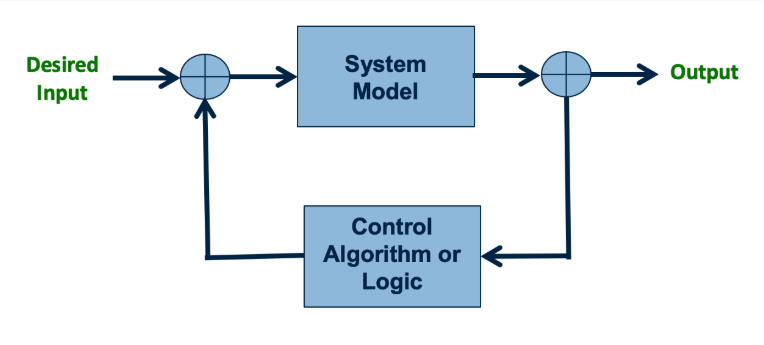

The image at the top of the post is a basic block diagram for a control system. It’s a dynamic system that’s meant to represent differential equations, dynamic flows, and physical systems that move. An engineer typically starts with a system model, which is a model of something, a behavior, or an activity. In the controls world, that might be something simple like an elevator or complex like a spacecraft. And, there is a model for its behavior.

For an elevator, it describes how the motor works and how the gears function. When the motor turns on, it explains the response rate. The control system is something to make the system do what you want. Let’s say we want the elevator to go to the second floor. The desired input is “go to the second floor.” This tells the system model to head to the second floor. The output measures its position – heading to the second floor. In the case of an airplane, it might be a performance parameter or something like straight, level, climbing, or diving. Then, the system measures the difference between what the model is doing and what the desired output is. That difference goes into the control logic, which comes back and usually that changes the control system.

If the elevator is far from the second floor, the logic may turn the motor on all the way, 90-100%, but as the elevator approaches the second floor, the logic says to start slowing down. The elevator keeps moving until it precisely reaches the second floor, i.e., when the output is zero. Once this happens, the control system input is zero. This model is of the system feedback logic for turning motors on.

Process for Designing Control Systems

- Determine the desired result

- Observe the system

- Hypothesize the model

- Test the hypothetical model

- Adjust the model until the results are able to be predicted

- Design and build the control logic

- Test the system

- Adjust the control logic until the desired results are obtained

I’ve found that you can take this engineering theory of how control systems operate and extend the model. If you’ve read any of my other posts on behavior like Rock Theory of Management, you see that I follow these eight steps. First, I decided that I didn’t want to rewrite my pitches and plans continuously. After observing the system for a time, I proposed that the reason management made decisions was based on what time it was rather than actual performance. My hypothetical model was a big change that I had to test, which was scary, but it worked well. I tuned the control system, and soon, management liked the approach.

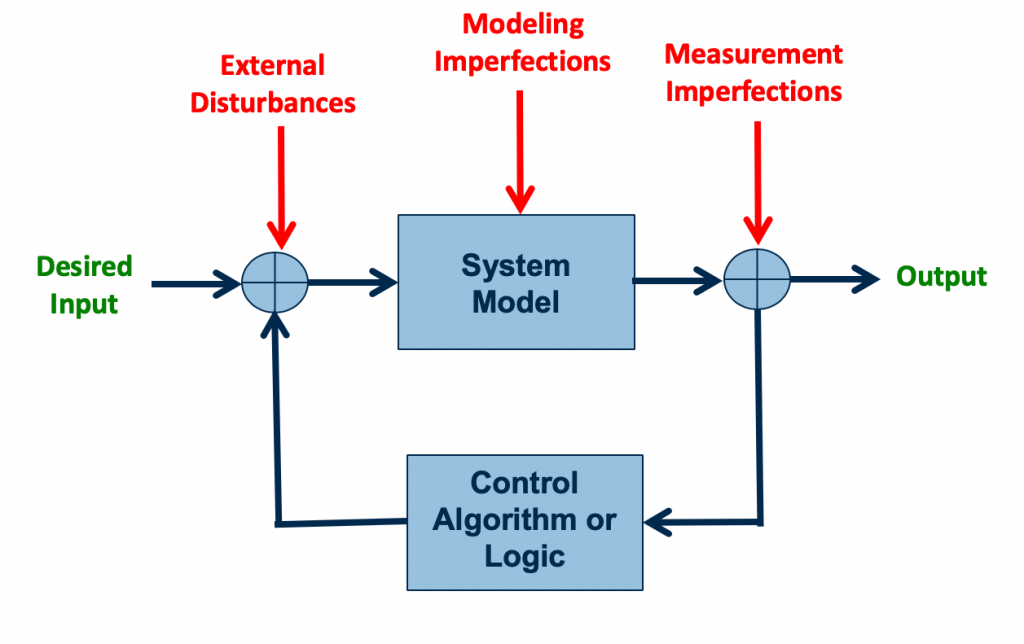

Robust Control Systems

To build a more robust system, it must be able to handle unknowable realities, such as external disturbances, modeling imperfections, and measurement imperfections. On an airplane, an external disturbance might be wind or turbulence. Sometimes, the model isn’t exactly right, leading to modeling imperfections. For example, when trying to model behavior in negotiations or what motivates people, you can’t predict the reactions precisely.

Measurements of performance can be imprecise as well. If you want to do something simple like reaching a monetary goal, then count the money. But if the goal is to get high performance out of an employee, one never knows if the highest performance was achieved. It’s hard to measure unless it’s perfectly objective, which rarely happens in the business world.

A control system must be able to handle these disturbances. Otherwise, it is an open loop control system. For an elevator with an open loop control system, the system might send the elevator to the first floor, turn the motor on for 33 seconds, and then turn it off. The elevator should be at the second floor. Now, this works great … unless the lubrication is worn down, the temperature changes, the motor starts to burn out, or the weight of the people in the elevator is different. There are too many differences to account for. To build a better elevator, the elevator should measure where it is currently and measure along the way to the second floor. The control system must take into account variables by receiving feedback. Control systems used in business situations require these robust systems.

Business Application

One definition of strategy is “plan of action designed to achieve a particular goal.” Strategies and tactics fit nicely into control systems. They have a plan with a feedback control system to go from a desired goal to what you want.

I have several models related to this, such as the pie model, Congressional staff, and study habits. Build a model for what you think motivates the situation, and hopefully, it’s resistant to disturbances and imperfections in your system model and measurements.

Share this Post